Smart, Swift, Safe: Mobility Solutions Revolutionize Manufacturing

Manufacturers across the globe are looking for new ways to reduce downtime, stay efficient, and streamline their supply chains. Why? Because even small improvements can equate to reduced costs and increased profits.

Especially as COVID-19 has negatively impacted companies across all industries–from disrupted supply chains to massive shifts in demand–manufacturers are turning to an array of new technology to improve their financial positions and achieve their goals. They are using the likes of AI and machine learning, augmented and virtual reality, sensor technology, and the Industry Internet of Things (IIoT) to improve their processes and increase efficiencies.

However, to truly make the most of these new technologies, businesses must first ensure that they are communicating in a seamless, timely, and accurate fashion. The only way to achieve this is with the support of the right enterprise mobility solutions.

Challenges for Manufacturers

COVID-19 uncertainties

Already grappling with the uncertainties of new tariffs in 2019, manufacturers are facing yet another major hurdle during the COVID-19 pandemic. The pandemic impacted manufacturers early in the year–disrupting supply chains and slowing production in many verticals.

A new industrial revolution

Industry 4.0, or the fourth industrial revolution, has introduced massive changes to the face of manufacturing. New technologies – from 5G to the Industrial Internet of Things and from AI to mobile robotics – are kick-starting a Renaissance in the industry. They offer new opportunities to increase efficiency but are also disrupting existing ways of working.

Information gaps

Despite cutting-edge technologies appearing on the scene, communication is still a struggle for many manufacturers. Within a business or even a single plant, different formats of information and a patchwork of devices make it difficult to stay connected. As a result, enterprise mobility in the manufacturing market is expected to grow 22.9% every year for the next five years.

Rising expectations

The pace of production and delivery has never been higher. With no room for inefficiency, there’s more pressure on staff to make good decisions quickly. Plus, customers want to know what’s happening with their orders in real-time. To live up to these expectations, staff need to get hold of accurate supply chain information instantly.

Regulations and safety standards

In manufacturing, lots of workers spend long periods of time alone or off-site. Many also handle dangerous substances. Already, mobile on-and-off safety alarms are a legal requirement in Germany for workers who patrol sites at night or who work in secluded areas. Safety regulations will only get tighter in other regions, too.

How Mobility Can Help

Reduce Downtime

Any delay can decrease output and waste labor resources. This can directly impact a business’s bottom line, not to mention their reputation. As such, mobile solutions from Spectralink are uniquely designed to streamline communication, reduce response times, and make plants more efficient. With our combination of wireless systems and production monitoring equipment, manufacturing personnel can quickly and accurately convey vital information.

Troubleshoot problems more quickly

If something goes wrong, the issue needs to be fixed fast. With enterprise mobility, manufacturing managers will receive alerts directly to their devices. Then, they’ll be able to quickly find the closest technician using the real-time location system. Technicians can then view details of the problem and discuss the situation over the phone while en-route.

Keep inventory moving

To move products through the supply chain quickly and effectively, manufacturers need real-time communications they can rely on. They need handsets that offer a long battery life and talk time, plus the kind of durability that won’t let them down. They also need to scan codes on pallets, check stock, and order additional parts whenever the need arises. Having a device can give them everything they need to keep things moving.

Improve worker productivity

Manufacturing personnel can use a Spectralink phone as a shared resource. This means they can use them as and when needed, across shifts and with individual log-ins. What’s more, the batteries and hardware are built to last. Plus, they can provide over 10 hours talk time from one charge. Conveniently, users can also charge spare batteries at the same time.

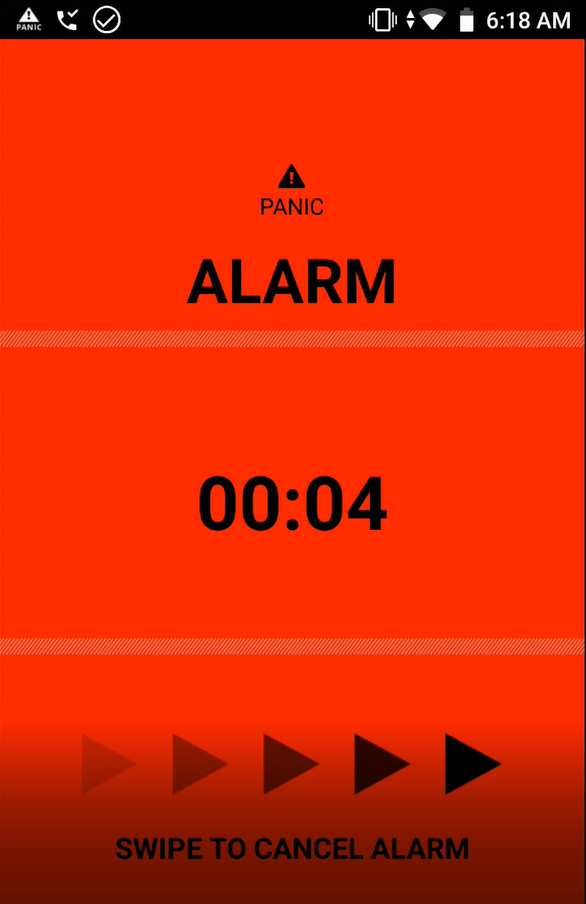

Increase safety

Manufacturing environments are some of the most dangerous. Not only are they vast, they’re loud and are often filled with mechanical and/or chemical hazards. Employees can use Spectralink phones with SAFE functionality which includes panic buttons and built-in motion detectors linked to their security system and central control room. They can use the push-to-talk function to get in touch with co-workers quickly. And, if an accident does occur, they can use the emergency alert at the press of a button.

Devices built for industrial environment

Different types of sites have different requirements; chemical sites for example sometimes need ATEX handsets. What most manufacturers have in common, however, is the demand for rugged devices that are resistant to drops, spills, and tough environments.

Conclusion

To future-proof their business, manufacturers need to understand the increasingly important role that making informed enterprise mobility choices is going to have on their productivity, efficiency, compliance, safety, and overall competitiveness. Contact us to learn more.